-

How to make aluminum cup?

At present, in events such as stadiums or some large chain store, aluminum cups are occupying more and more markets as a substitute for plastic cups.

It also means people who are interested in this industry are curious about the production process of this metal cup. As China’s top supplier of aluminum products, SHINING ALUMINUM PACKAGING CO., LTD will briefly introduce the complete production process (Click here for video) of aluminum cups.

First, Trimming. This step is to shape the aluminum cup from the original aluminum block. The raw materials were originally purchased in the form of aluminum plates. They will be processed into thick aluminum sheets by the special machine and then turned into the original aluminum cup by the stamping machine. After that, they will be cut off the rough edges and become the aluminum cup roughcast.

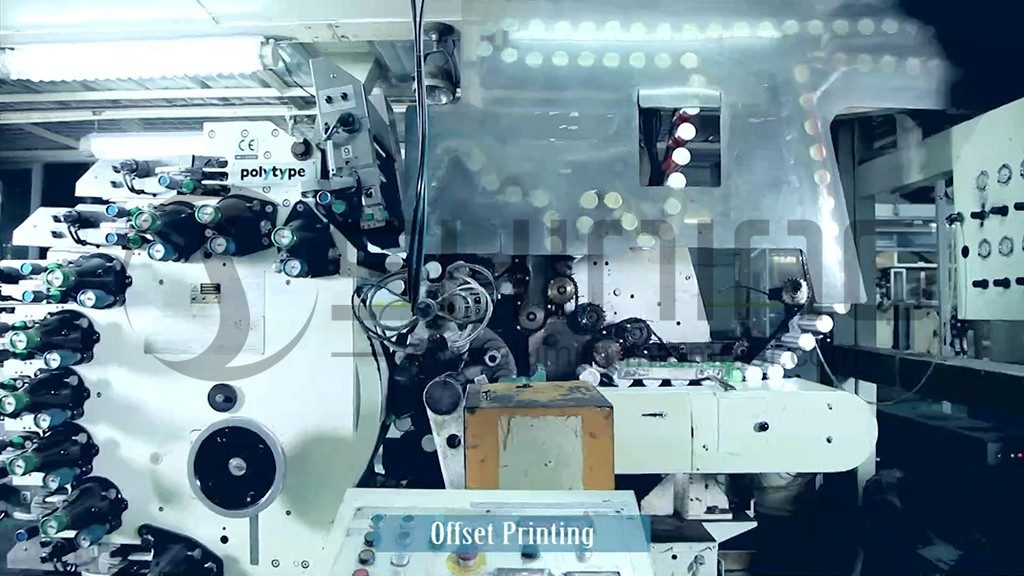

After the trimming, the Printing process is followed. The cups that have been formed will be polished first and cleaning. After this, they will be internally coated with food-grade paint, and then externally printed. At the end of the printing process, a layer of varnish is usually added on the outside of the cup to enhance the printing effect.

It is worth noting that, in the above printing process, each time a printing is performed, the cups need to be dried.

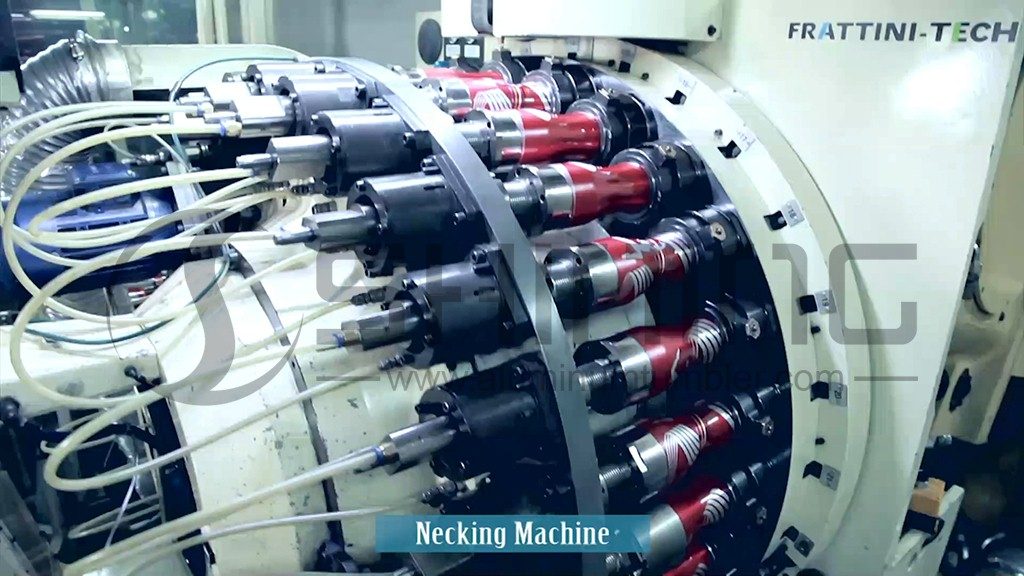

After the printing step is completed, the bottle will be subjected to Flexible Plasticity by a special machine to form the specific shape required.

After the above steps, a beautiful aluminum cup is finally completed! As long as it passes several different Inspections (including missing print inspection, color and font inspection, and inner coating conductivity test), it can be Packed and Shipped!